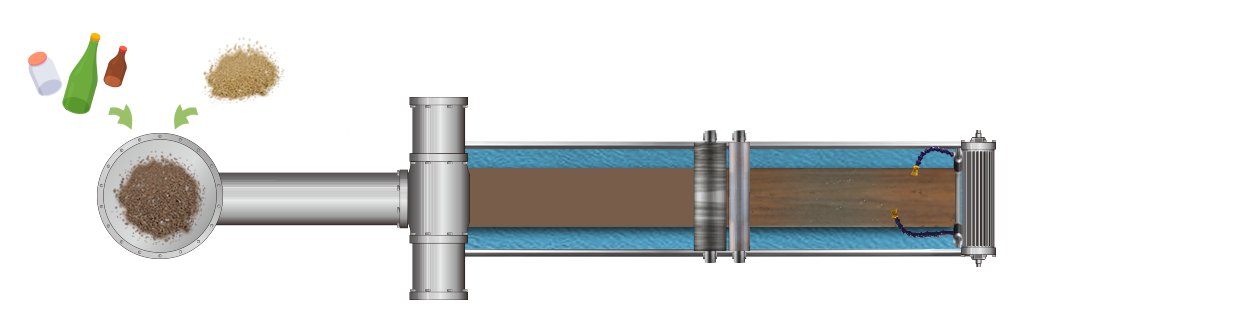

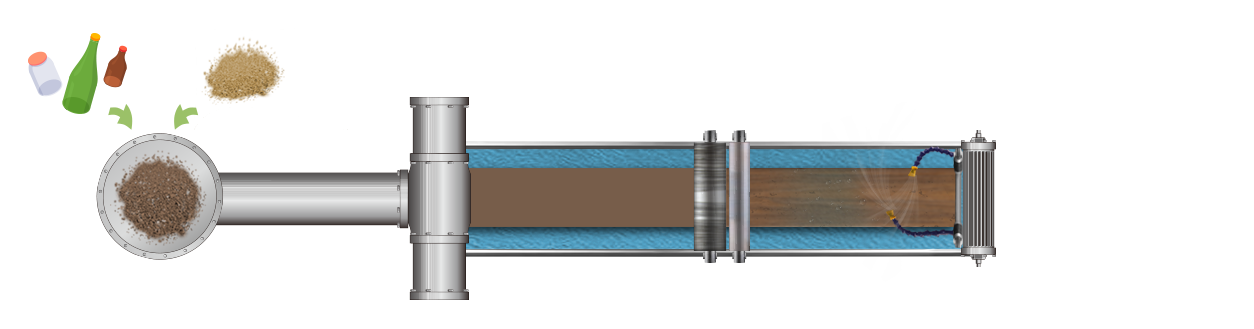

Raw Materials

Firstly all the raw materials will be mixed together according to the proportion of formula, and stored in this silo. Other processing aids will be measured separately and be blend together.

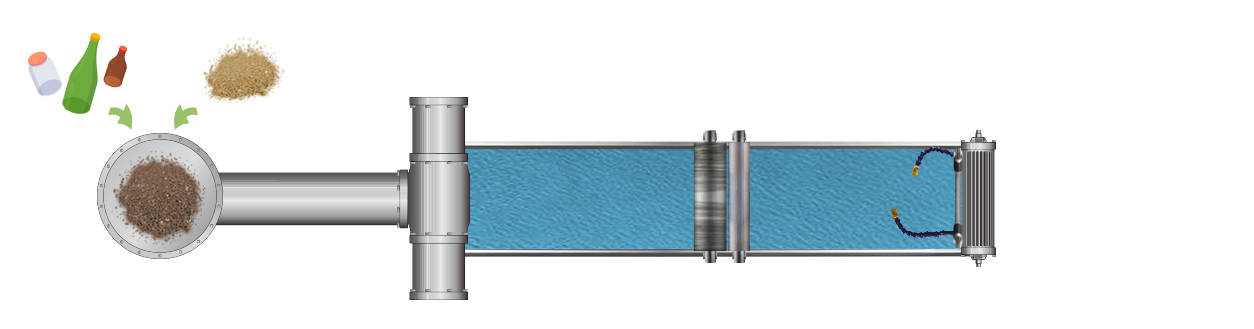

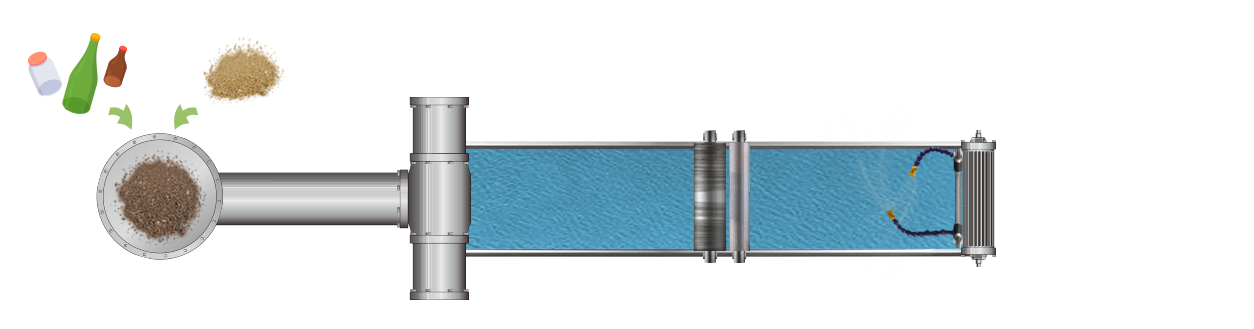

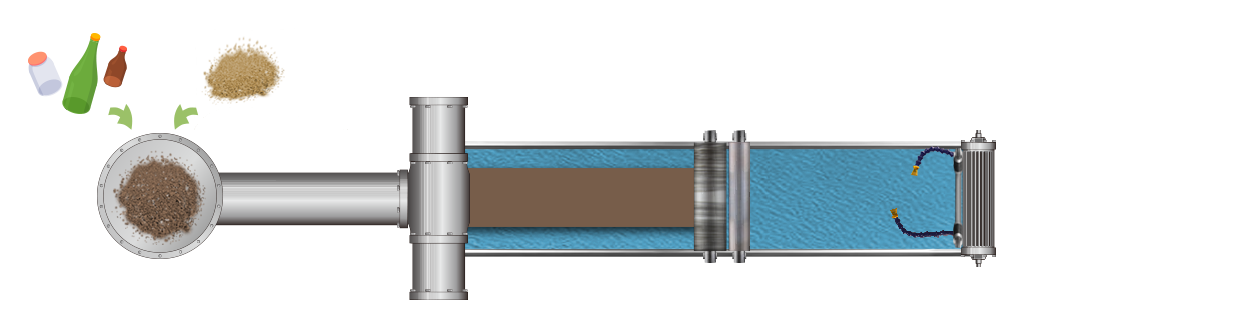

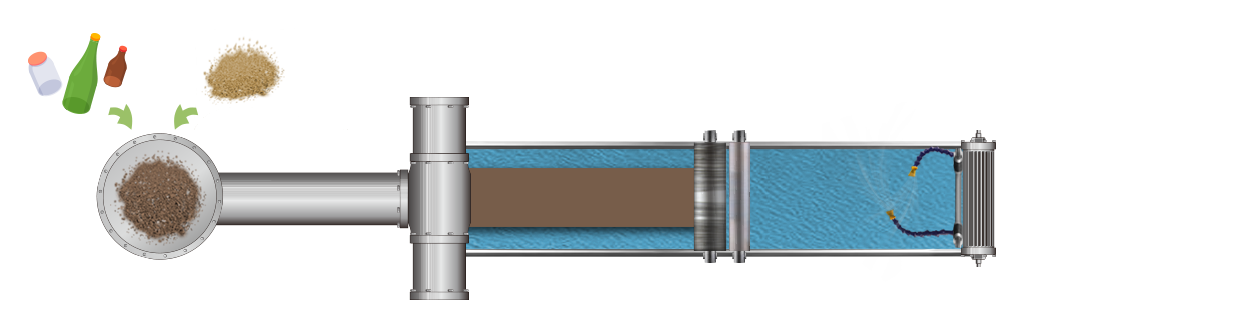

Extruding

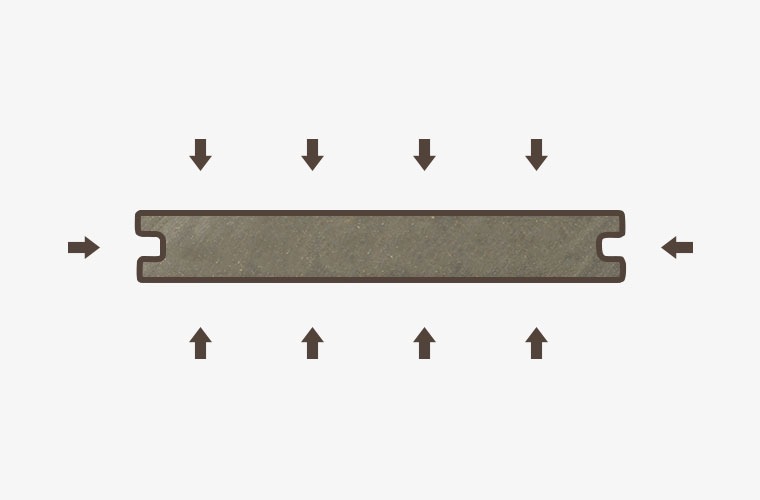

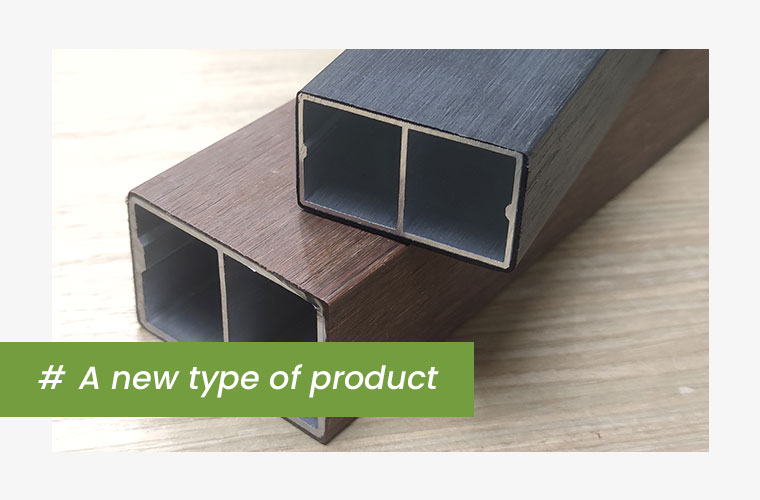

For co-extrusion products, the shield and core are extruded together under a very high-temperature mould simultaneously, so there are no adhesives or chemicals that are harmful to the environment.

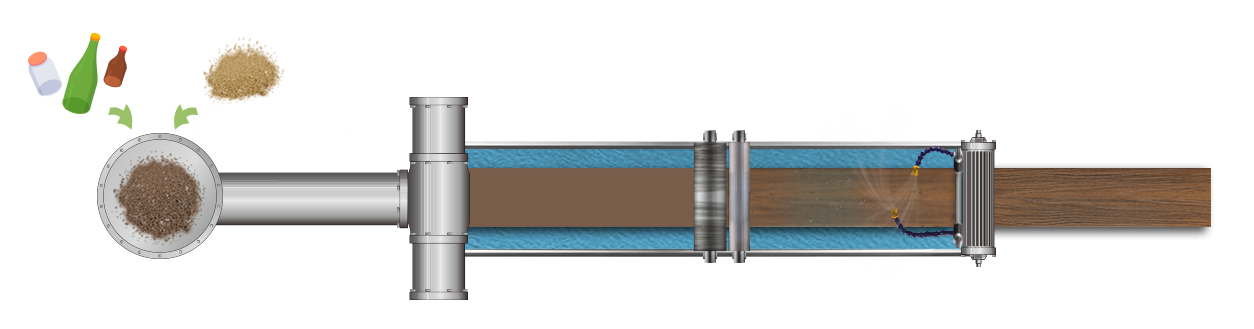

Embossing

We have embossed two sides differently. On one side, you have a very even finish surface. On the other, you have that rustic milled look where you get a lot of that character which is really hard to find.

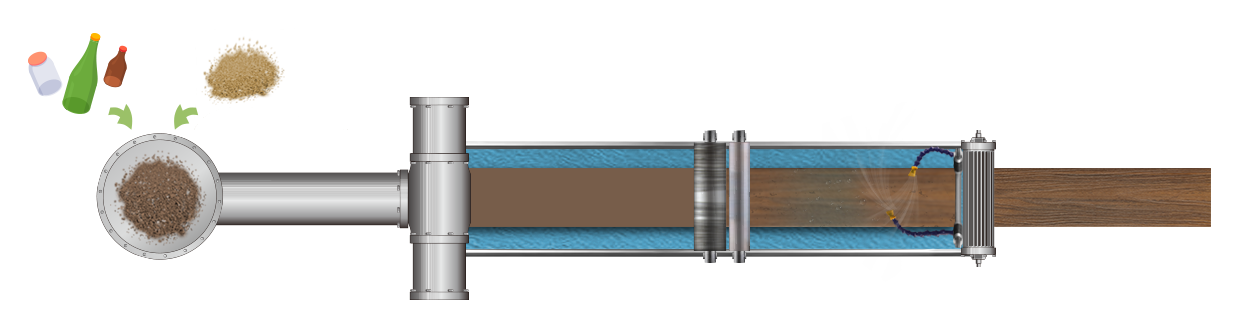

Sanding

Sanding can make our products better obtain wood appearance and give the shield protection against color fading. If the product does not go through the sanding procedure, the surface of it is mainly plastic. If we sand the plastic part, the color fading will not easily.