8 Important Facts to Know Before Building Your Composite Deck

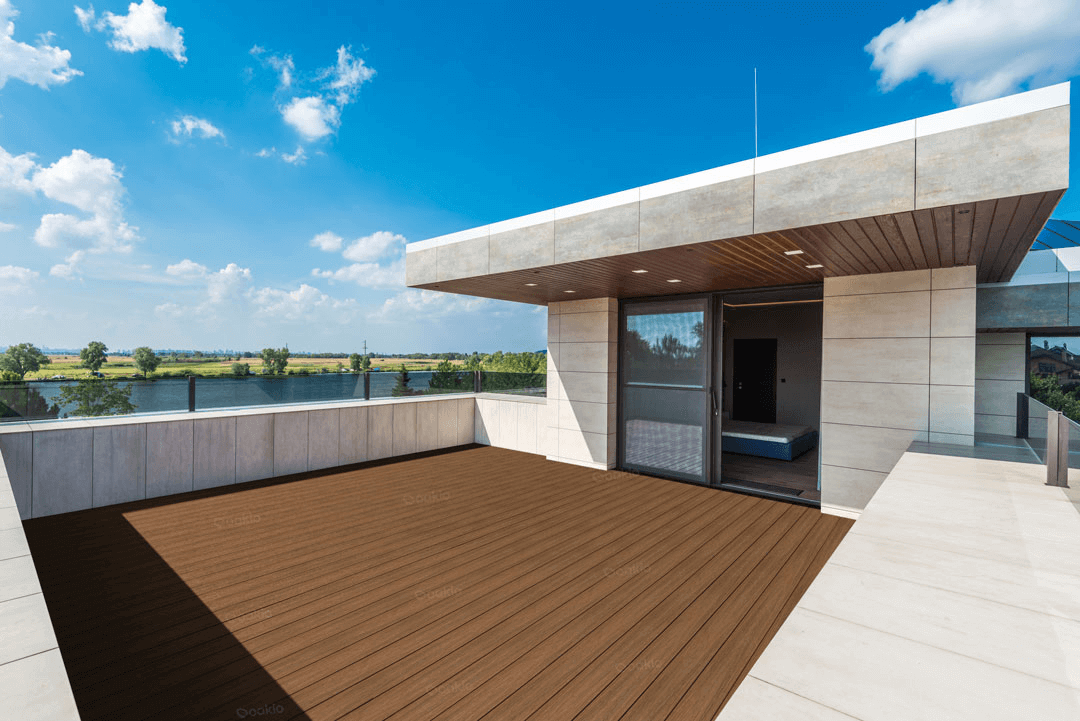

Wood plastic composites (WPC) have become a well-known choice for various construction applications like flooring, cladding, and decking because they are really easy to use, durable, and eco-friendly.

WPC is also a sustainable material when building a composite deck, and offers excellent resistance to weather and daily wear and tear. But before you build a deck, it pays to be prepared so you can save time, money, and effort—all to ensure a successful project.

8 Important Facts to Know Before Building Your Composite Deck

Composite decking is well-known for its durability, sustainability, and low maintenance features compared to traditional wood. But before you build one, there are various facts you need to note before you buy WPCs for your deck.

#1: Composites May Change Colors Early in Their Use

WPCs come in a variety of colors and textures, giving homeowners customization options to match their existing home’s aesthetic. However, it’s good to note that composites may slightly change colors as exposed to sunlight which happens as a result of weathering.

Weathering causes photodegradation—where UV rays in sunlight break down compounds in the wood and plastic, temporarily causing colors to slightly fade. But over time, the composites should stabilize into their original color.

The extent of this color change depends on various factors, such as the composition of the WPC itself, the use of UV stabilizers, and how exposed is the composite in question. Homeowners should take note that when selecting deck colors, the shade they’ll see initially is not the true color of the material.

Choosing high-quality WPC with UV inhibitors like Proshield can help minimize initial color fading.

#2 Many WPCs are Mostly Recycled

WPCs are renowned for being sustainable, and it’s actually the top option for homeowners with material sustainability in mind. In fact, many composites are made from recycled materials—whether plastic or wood, then blended and bonded together with additives, and molded into different shapes.

Recycled plastics such as polypropylene (PP) and polyethylene (PE) provide strong moisture resistance, while recycled wood fibers add tensile strength and texture that results in a natural wood look. This blend of materials results in a strong but eco-friendly material that reduces waste and promotes recycling.

When looking for WPCs, you can check the percentage of recycled content in the product to help you decide if you’re looking for a more eco-friendly WPC brand.

#3 WPCs Can Also be Recycled at the End of Their Use

WPCs can also be recycled at the end of their life, which shows that sustainability extends beyond production. Composite boards can be recycled into new WPC products and other plastic-based materials, in contrast to traditional wood—which frequently ends up in landfills or just rots.

To produce new composites, the recycling process usually entails shredding old WPCs, eliminating impurities, and then remelting and remolding the material. This prolongs the use cycle of materials, decreases waste, and lessens the need for new plastic components.

Most manufacturers urge users to return used WPCs for reuse, though not all of them have recycling programs. Selecting companies that support recyclability guarantees a more sustainable decking option and a smaller environmental impact.

#4 Composite Boards are Sometimes Slippery When Wet

Slip-and-falls are an issue to any outdoor deck, and composite boards aren’t exempted. The majority of WPCs provide better traction than traditional wood decks, but most cheap WPCs don’t possess enough slip resistance, which increases the risk of slipping.

If you’re building a deck in a humid and wet climate or near a pool or any other bodies of water, we recommend adding anti-slip devices like outdoor mats, non-slip coatings, and textured boards. Adding an under-deck drainage system can also help by drawing water away from the deck, ensuring the surface is dry.

Periodic cleaning is also necessary to prevent the development of algae or mold since these increase the likelihood of slipping on WPC surfaces. You can also opt to buy high-quality slip-resistant boards like the Elashield.

#5 It’s Possible to Build an Outdoor Cooking Space on a Deck

Outdoor cooking has remained a valued tradition, and many homeowners dream of incorporating grills or complete kitchens within their deck area. And while it is possible with WPCs, it does require some careful planning.

Heat protection is necessary, as composite boards may melt or change color when subjected to heat. Having a heat-resistant mat, or placing your cooking space on a heat-resistant stone or metal surface is often recommended. Additionally, proper ventilation must be taken into account to prevent excessive smoke and heat buildup.

You’ll also need to follow local building codes which lay out certain requirements for outdoor kitchens on decks, especially concerning fire safety. You can opt to use heat and fire-resistant composites, though they are commonly more expensive upfront.

#6 With Proper Construction, Deck Hot Tubs are Possible Too

A deck hot tub can be a luxurious and elegant part of your outdoor space, but structural supports should be built to support its weight. Hot tubs are already heavy, and if you fill them up with water, they get extremely heavy and must be supported by reinforced joists, beams, and footings to prevent a collapse.

Should you want to add a deck hot tub, you’ll need to talk to a structural engineer or contractor to make sure your deck can support the increased weight.

Good water management must also be implemented—a drainage system in place keeps water at bay, preventing mold or structural problems caused by prolonged water exposure. Adding slip-resistant mats surrounding the tub should be done too to prevent slipping accidents.

#7 Scratches and Scrapes Can Shorten the Lifespan of Composites

Composite boards have protective external layers that enhance durability, but they can still be scratched and scraped with enough use. Good handling during the installation and regular maintenance, like periodic cleaning and inspections can help lengthen their lifespan.

Dragging heavy furniture and dropping sharp and dull objects may scratch and scrape the surface. Using abrasive cleaning tools and materials can also cause visible marks. To prevent this, we recommend using furniture pads and avoiding rough scrubbing—just a soft-bristled brush would suffice.

It’s also a great choice to use high-quality WPCs with scratch-resistant coatings for added scratch and scrape protection. Though they’re not entirely scratch-proof and will one day show minor signs of normal wear and tear, these surface marks might disappear with some buffing out.

#8 Not All Wood Plastic Composite Boards are Equal

WPCs vary in quality, and not all boards are as long-lasting as the other ones. Some are more suited for certain climates or applications, and some are just made to be inferior. Top-end WPC products such as Oakio’s offer more strength, fading resistance, and longevity.

Lower-quality composites often have the least UV protection, wear resistance, or structural stability, resulting in a relatively shorter lifespan—so it’s best to avoid these as possible.

Choosing the appropriate WPC will make your deck durable and stunning for years if not decades. Also, considering the specs and customer reviews can help you build a composite decking system that lasts the test of time.

Conclusion

In summary, by understanding these 8 facts, you’ll now be able to build a safe, durable, and sustainable composite deck. Whether you’re looking for an eco-friendly deck material, thinking of adding an outdoor kitchen or a hot tub deck, or just exploring WPC qualities, Oakio’s got you!

With Oakio, your WPC deck concerns are attended to with our high-quality products designed for different scenarios—we have slip-resistant, fire and heat-resistant, scratch-resistant, anti-static, elastic, stain-resistant, and UV-resistant products for you to choose from!

Trending Reading

What Are the Differences Between the WPC Board and PVC Board?

[2025 Update] How Long Does WPC Decking Last?