How Co-Extruded WPC Materials Enhance Durability in Seawater Environments

WPC materials, widely used in outdoor construction, must withstand tough conditions. Their performance in seawater environments—especially with HDPE-based composites—has become a critical area of research for enhancing durability and structural stability.

How Seawater Affects WPC Material Performance

Exposure to corrosive marine environments significantly affects the longevity of WPC materials. Studies show that simulated seawater and acid rain severely weaken mechanical strength and surface integrity, especially in HDPE-based composites. Of the tested combinations, eucalyptus fiber/HDPE composites showed the best bonding quality and mechanical resilience, while poplar/HDPE fared worst due to fiber agglomeration and poor interface bonding.

The Role of Interface Bonding and Fiber Composition

The degradation process in WPC materials under seawater exposure often begins at the fiber-matrix interface. Cracks and voids allow saltwater penetration, accelerating damage. Additionally, seawater acts like a plasticizer for cellulose in plant fibers, reducing their rigidity and contributing to mechanical decay. The result is increased color fading and surface defects over time, which compromise both aesthetics and performance.

Advancements in Co-Extruded WPC Materials

To address these challenges, manufacturers are turning to co-extruded WPC solutions. These second-generation materials offer significant improvements:

- Multi-layer protection: A triple-layer nanomaterial coating—used in aerospace-grade graphene composites—provides long-term protection against fading, cracking, and deformation.

- Enhanced density: Co-extruded profiles maintain optimal density (~1.2 g/cm³), balancing structural strength and flexibility.

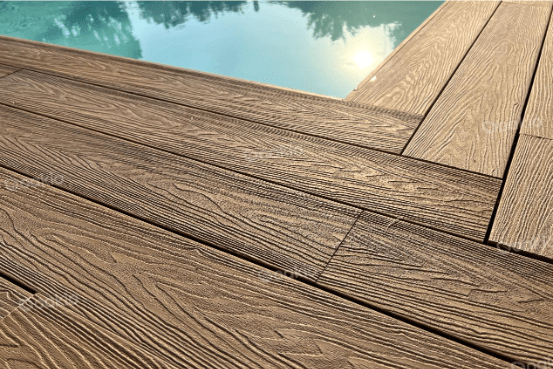

- Superior aesthetics: Variegated textures and wood-like finishes offer high-end appeal without sacrificing durability.

- Weather resistance: UV, moisture, and mold protection make co-extruded WPC ideal for coastal applications.

Oakio’s Proshield and Elashield collections exemplify these innovations, using premium shields that fully encapsulate the core material. This prevents moisture ingress and prolongs lifespan even in harsh marine climates.

Addressing Fire and Environmental Safety

Despite WPC’s eco-friendly image, fire safety remains a concern, especially with HDPE-based composites. Common polymers like PE and PVC have low oxygen indices and emit harmful gases when ignited. Solutions involve incorporating halogen-free, phosphorus-based flame retardants like aluminum hypophosphite (AHP), which enhance fire resistance without compromising environmental standards.

Researchers also explore the challenge of integrating natural fibers with non-polar polymers like HDPE. Compatibility issues affect dispersion and bonding, reducing mechanical performance. Improved coupling agents and modified processing techniques (like precise temperature control) are key to achieving better performance composites.

Selecting Quality Recycled Plastics for HDPE-WPC

The quality of recycled plastics used in WPC core material greatly influences final product performance. Ideal sources include:

- Small hollow plastic bottles (e.g., milk jugs): Excellent strength and dimensional stability.

- Cable sheathing material: High tensile properties but may shrink post-installation.

Low-grade or mixed-source recycled plastics can lead to defects like unmelting spots, cracking, or uneven color, emphasizing the importance of thorough raw material screening during production.

Conclusion

The future of WPC materials lies in innovations that address environmental durability, mechanical integrity, and aesthetic longevity. Co-extruded WPC technologies like those used by Oakio represent a significant leap forward—combining eco-friendliness with advanced engineering to meet the demands of marine and coastal construction.

Discover Oakio’s range of seawater-resistant, co-extruded WPC decking and cladding solutions—designed to endure, built to last.

Trending Reading

What Are the Differences Between the WPC Board and PVC Board?

[2025 Update] How Long Does WPC Decking Last?