Water Absorption Testing of Co-Extruded Composite Decking: Performance & Standardization

In recent years, the wood-plastic composite (WPC) industry in China has experienced rapid growth, with co-extruded composite decking emerging as a major innovation in the field. Thanks to advances in extrusion technology and surface engineering, co-extruded WPC has become the material of choice for outdoor applications requiring superior durability and weather resistance.

Among its many advantages, water absorption resistance stands out as a critical performance indicator. This article explores the testing of co-extruded composite decking’s water absorption performance, the limitations of existing testing standards, and the direction for future improvements in material quality control.

What is Co-Extruded Composite Decking?

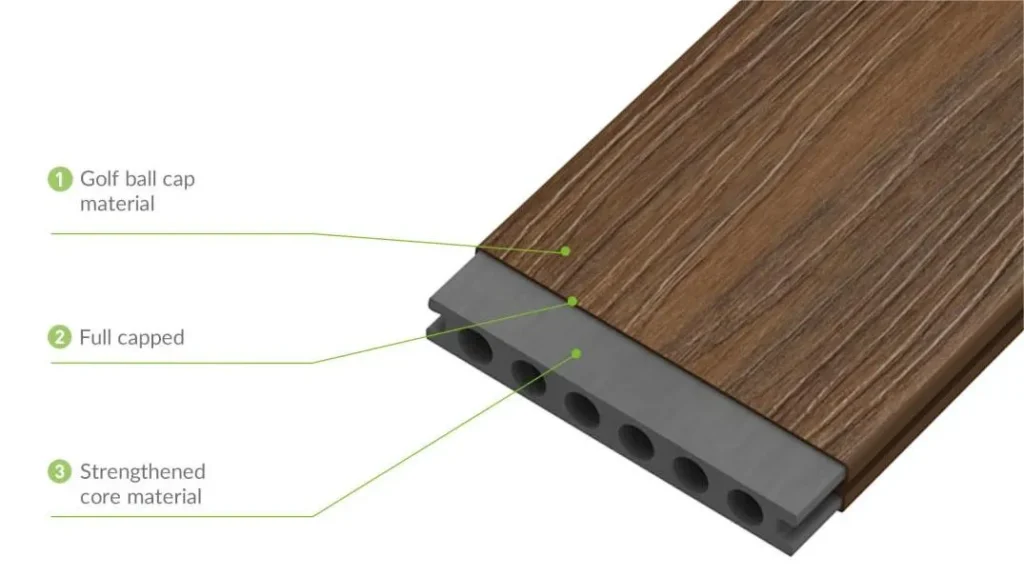

Co-extruded composite decking is a type of WPC product manufactured using a multi-layer extrusion process. During production, one or more functional surface layers are bonded to a WPC core, forming a protective outer shell. This surface layer is typically composed of advanced polymer materials that offer increased resistance to UV radiation, moisture, staining, and mechanical wear.

Compared to traditional WPC products, which are uniform throughout, co-extruded decking delivers dramatically improved water resistance, dimensional stability, and overall longevity. These attributes make it highly suitable for outdoor flooring, cladding, fencing, and similar applications that must endure prolonged environmental exposure.

The Challenge with Existing Testing Standards

Despite its growing popularity and technical superiority, co-extruded composite decking currently lacks specific industry standards tailored to its unique structure and behavior. Most manufacturers and testing facilities continue to rely on legacy standards developed for non-co-extruded WPC products.

A commonly used benchmark in China is GB/T 24508-2020 – Wood-Plastic Composite Flooring, which is categorized under surface-treated WPC boards. While applicable to some aspects of co-extruded products, this standard does not fully reflect the performance characteristics of multi-layer decking, especially concerning water absorption and dimensional change.

As a result, using outdated standards may lead to inaccurate assessments, either underestimating or overestimating the product’s actual performance. The need for dedicated testing procedures for co-extruded decking is becoming increasingly urgent as the market matures.

Key Differences in Water Absorption Behavior

The difference in water absorption between traditional WPC and co-extruded WPC lies primarily in their structural composition. Standard WPC materials, when exposed to water, tend to absorb moisture uniformly throughout the board, leading to overall swelling and deformation. This process is relatively predictable and straightforward to measure using conventional testing methods.

In contrast, co-extruded decking is engineered with a protective surface layer that significantly reduces water ingress from the exposed faces of the board. Water can typically only enter through cut edges or unsealed ends. As a result, deformation often occurs only at the board’s ends after prolonged immersion, while the central body remains stable.

This creates a performance profile that existing testing methods are ill-equipped to evaluate. Co-extruded products may pass basic short-term absorption tests with ease, but without extended immersion or targeted edge exposure, meaningful data may be difficult to collect.

Testing Results: Co-Extruded vs. Traditional WPC

Experimental comparisons between co-extruded and traditional WPC materials highlight the superior water resistance of co-extruded products. In standard 24-hour and 72-hour immersion tests, co-extruded boards showed significantly lower water uptake and dimensional change compared to non-coated alternatives.

In some cases, the change in dimensions was so minor that the instruments used could barely detect any measurable deformation. While this reinforces the material’s strong resistance to moisture, it also points to the limitations of short-duration testing protocols for high-performance products.

To obtain more reliable and representative results, longer immersion durations are necessary. According to the EN 15534-4:2014 standard, a 28-day water immersion test is recommended for evaluating water absorption and dimensional stability. This extended method allows for a more comprehensive analysis, particularly for products like co-extruded decking that exhibit slow and localized moisture penetration.

Moving Toward Accelerated Testing Methods

Although the 28-day immersion method provides valuable insights, its lengthy duration poses practical challenges for manufacturers, especially those needing quick production cycles and routine quality checks. To address this, researchers and industry experts are now exploring accelerated testing methods that can replicate long-term immersion conditions in a shorter timeframe.

One promising approach involves subjecting co-extruded WPC samples to high-temperature water immersion, which speeds up the rate of moisture diffusion through the exposed ends. By establishing a correlation between high-temperature and ambient-temperature absorption results, it may be possible to create a reliable accelerated test protocol.

Such advancements would not only improve efficiency in product development and quality assurance but also facilitate the creation of standardized benchmarks specific to co-extruded decking.

Conclusion

Co-extruded composite decking represents a significant leap forward in outdoor material technology, offering unmatched resistance to moisture, fading, cracking, and wear. Its multi-layer structure poses unique testing challenges, particularly in evaluating water absorption and dimensional change.

As the industry evolves, so must the testing methodologies and standards used to assess product performance. Transitioning from legacy WPC standards to protocols designed specifically for co-extruded materials—such as extended immersion or accelerated soaking—will enable more accurate quality control, support product innovation, and ensure consumer confidence in this next-generation decking solution.

By investing in research and establishing clear testing guidelines, manufacturers can not only enhance the durability of co-extruded decking but also contribute to a more sustainable and efficient building materials industry.

Trending Reading

What Are the Differences Between the WPC Board and PVC Board?

[2025 Update] How Long Does WPC Decking Last?