Why Water Absorption Testing Standards Must Evolve for Co-Extruded Composite Decking

In recent years, wood-plastic composites (WPC) have become increasingly popular in the global building materials market, especially in outdoor decking. Among them, co-extruded composite decking has emerged as a premium product thanks to its enhanced performance characteristics, particularly in water resistance and durability. However, current testing standards have not kept pace with this technological advancement, leading to a growing need for updated and specialized testing methods. This article explores why it’s time to evolve water absorption testing standards for co-extruded composite decking.

What is Co-Extruded Composite Decking?

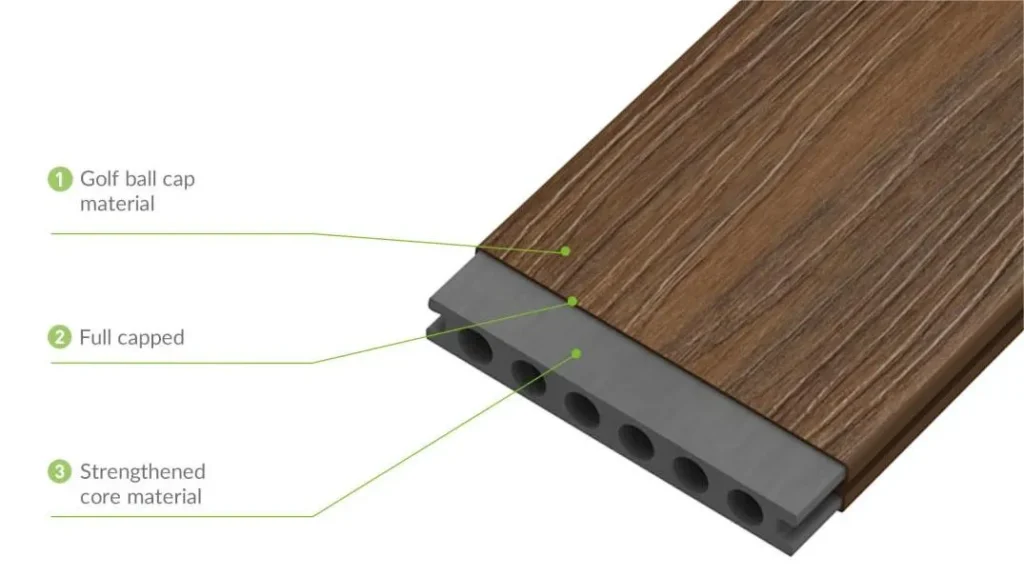

Co-extruded composite decking refers to WPC boards manufactured with a specialized outer layer made from functional polymers. This layer is applied through a co-extrusion process, bonding tightly to the core material. The result is a product with enhanced protection against moisture, UV radiation, staining, and mechanical wear.

Unlike traditional (non-co-extruded) WPC, which has a uniform composition throughout, co-extruded decking features a multi-layered structure that serves as a barrier against external elements. This advanced design not only improves the deck’s appearance and longevity but also significantly alters how it behaves under moisture exposure—an important factor for outdoor applications.

Why Water Absorption Testing Matters

Water absorption and dimensional stability are critical indicators of performance for any outdoor decking product. In humid or rainy climates, excessive moisture can lead to swelling, warping, cracking, or even microbial growth in some WPC products. For consumers and professionals alike, understanding how decking responds to water is essential for selecting the right material.

Testing standards serve as benchmarks for product quality and reliability. But when new technologies like co-extrusion are introduced, legacy testing protocols may fail to provide accurate or relevant results.

How Co-Extruded Decking Outperforms Traditional WPC

One of the defining benefits of co-extruded composite decking is its low water absorption rate. Thanks to its high-performance polymer cap layer, moisture is effectively blocked from penetrating the surface. Water can only enter through exposed cross-sections, such as cut ends, significantly reducing the overall impact.

According to comparative studies, co-extruded WPC absorbs less water over 24 to 72 hours than non-coated WPC. Moreover, its dimensional changes (expansion or warping) due to water absorption are minimal—often too small to measure accurately during short-term immersion tests. This slow and limited absorption rate means co-extruded products maintain their structural integrity and appearance far better than their traditional counterparts, even after long-term exposure.

Limitations of Current Testing Standards

Despite the superior performance of co-extruded decking, it is still commonly tested under national standards designed for non-co-extruded WPC—such as GB/T 24508-2020. These standards were developed based on materials with a homogeneous composition, which absorb water differently.

When applied to co-extruded products, these tests often fail to capture the true behavior of the decking. For instance:

Short-duration immersion tests may not reveal meaningful absorption or expansion.

Evaluation metrics may not align with the localized absorption pattern typical of co-extruded materials (i.e., only at cut ends).

As a result, product performance might be underestimated or mischaracterized, hindering both quality assurance and innovation.

The Case for New Testing Protocols

To address this issue, industry experts have begun examining alternative standards, such as EN 15534-4:2014, which includes a 28-day water immersion test. This longer-duration test allows sufficient time for meaningful data to be collected from co-extruded products and provides a more realistic picture of long-term moisture behavior.

However, the downside is the extended testing period, which slows down production cycles and delays time-to-market. To improve efficiency, researchers are exploring accelerated testing methods using elevated water temperatures. By analyzing the relationship between high-temperature immersion and long-term, room-temperature results, it’s possible to develop faster, more accurate testing protocols.

These updated methods would not only improve quality control but also support the development of new co-extruded materials with even better performance.

Future Outlook: Standardization Is Key

The evolution of WPC technology demands a corresponding evolution in testing and certification. As co-extruded composite decking becomes mainstream, the lack of specific standards poses a risk to both manufacturers and consumers. Without proper evaluation methods, innovative products may be overlooked, or inferior copies may flood the market, damaging consumer trust.

To ensure consistent product quality and encourage innovation, it is essential for the industry to:

Develop dedicated standards for co-extruded WPC.

Establish shortened, accelerated water absorption tests.

Promote international collaboration for harmonized testing protocols.

Conclusion

Co-extruded composite decking represents a major advancement in outdoor building materials, offering superior water resistance, dimensional stability, and longevity. However, the current testing standards are not fully aligned with its performance characteristics. It’s time for the industry to recognize these differences and adopt updated testing methods that reflect the true capabilities of modern materials.

By doing so, we can ensure more accurate quality control, faster product development, and increased consumer confidence in this growing market segment.

Trending Reading

What Are the Differences Between the WPC Board and PVC Board?

[2025 Update] How Long Does WPC Decking Last?